The skin of Marmox Multiboard & Fireboard has been designed to offer the optimum level of porosity to allow cement based, lime-based and silicone-based render systems to bond to it.

Which Marmox products for external render?

Marmox Multiboards are unaffected by variations in temperature, even when submerged in water or covered in frost. Multiboards can be used externally on walls to provide a layer of waterproof, insulating cladding which can be rendered upon.

Marmox Fireboards are completely weather resistant. They have the same surface as Marmox Multiboards and offer A1 rated fire protection and particularly good sound insulation, as well as thermal insulation. Marmox Fireboards are ideal for external render.

General Advice - Applying a Simple Sand/Cement Render

Marmox Multiboads & Fireboards both have a textured concrete surface which can be rendered, as any concrete surface can be.

Typically, a conventional mesh is still required to be placed over the whole surface area of most render boards. The mesh is generally pressed into the base layer of render, however, different render suppliers will have their own application instructions which must be followed.

The method to be followed is as though rendering onto a concrete surface.

Masonry Walls

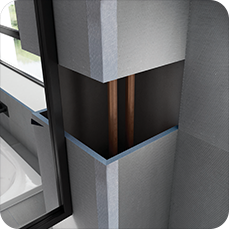

Marmox Multiboards can be fixed directly onto solid masonry walls, concrete and window reveals.

Fix to masonry surfaces with a continuous bed of cement-based tile adhesive and position the boards, staggering the joints. Marmox Self Adhesive Waterproof Tape can be used over the joints.

Render can be applied directly to the surface of the Multiboards.

Timber Frame

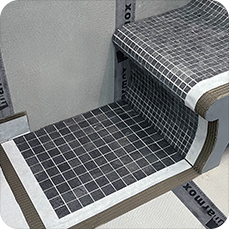

Marmox Multiboards can also be fixed onto battens.

If fixing onto timber battens, you must be confident that there will be no movement in your timbers as this could result in hairline cracks between the boards.

It is advisable to use Long (2400mm x 600mm) and Big (2400mm x 1200mm) Multiboards rather than Short (1250mm x 600mm) Multiboards. This is because the smaller the boards, the more joints, and therefore greater risk of any movement in the frame resulting in unwanted cracking between the boards.

Pictured to the right - 20mm (1250mmx600mm) Multiboards positioned in a landscape fashion with vertical studs at 625 centres.

Typical application on timber battens…

- Applying Multiboards:

- 4mm,6mm,10mm & 12.5mm – Not advised for external battened walls

- 20mm and above – Fix battening at every 600 centres (if using 1250x600 Multiboard in a landscape fashion, fix them at 625 centres)

- 20mm and above - Fix at 600mm centres

- For full details on this application please visit our specification page.

- A breather membrane should be included on the masonry if placing the boards on battens.

- The thinnest Marmox Multiboards which can be used for this application is 20mm - they should be fixed so that there is no movement whatsoever in the boards.

- Boards should be laid with staggered joints and fixed using screws and washers every 30mm along each timber. All vertical and horizontal edges of the board must be supported.

- Place a dab of Marmox MSP360, waterproof sealant over each screw hole prior to inserting the screw.

- A 5mm gap between vertically and horizontally laid boards should be left and filled with Marmox MSP360.

- To stop curing issues over the board joints, seal the boards together with Marmox MSP360.

- A mesh must cover the complete surface of the boards prior to applying the render, not just the joints. Around corners of window and door frames, additional mesh should be placed at 45O.

- The boards can now be rendered according to the manufacturers’ instructions.

Take into Consideration

Please take into consideration that Marmox Multiboard is non-breathable and therefore will stop water vapour generated within the building escaping through the normal path (through the walls), which could result in both surface and interstitial condensation within the structure. In order to prevent the risk of this, be sure to take steps to improve the ventilation.