As buildings become more energy efficient with better insulation it is important to address the thermal bridge at the wall floor junction. This can contribute up to 30% of a building’s total heat loss.

Thermal bridging at the wall-to-floor junction is a common issue in building construction that can lead to energy inefficiency and increased heating costs.

This occurs when there is a break in the insulation layer, allowing heat to transfer more easily between the interior and exterior of a building. Inadequate insulation or poorly designed junctions can create pathways for heat loss or gain, resulting in discomfort for occupants and reduced energy performance of the building.

The Floor to Wall Junction

One of the most critical areas where thermal bridging occurs is at the junction between exterior walls and floors. Traditional construction methods often involve the use of materials with high thermal conductivity, such as concrete or steel, at this junction. These materials can act as thermal bridges, allowing heat to bypass the insulation and escape or enter the building more easily. As a result, the temperature near the floor perimeter may be significantly different from the rest of the room, leading to discomfort for occupants and potential condensation issues.

To mitigate thermal bridging at the wall-to-floor junction, various strategies can be employed. One approach is to use insulation materials with low thermal conductivity, such as rigid foam insulation or insulated concrete forms (ICFs), to create a continuous thermal barrier between the wall and floor. Additionally, incorporating thermal breaks, such as insulated sheathing or structural thermal breaks, can help interrupt the flow of heat and reduce thermal bridging effects.

Why Should I pay Attention to Thermal Bridging?

Overall, addressing thermal bridging at the wall-to-floor junction is crucial for achieving energy-efficient buildings and improving occupant comfort. By implementing appropriate insulation strategies and design considerations, builders and designers can minimise heat loss or gain, reduce energy consumption, and create more sustainable and comfortable living environments.

Taking the lead from the EU’s Energy Performance and Buildings Directive, all building regulations in the UK and Ireland state the following:

“The building fabric should be continuous over the whole building envelope and constructed so that there are no reasonably avoidable thermal bridges in the insulation layers caused by gaps in the various elements.”

1. Reducing Thermal Bridging in Wall to Floor Junction Designs

Cold bridges occur where the wall meets the floor but for many years it wasn't possible to place insulation under a supporting wall because the insulation would have been crushed. It was for this reason that Marmox Thermoblock was developed.

Thermoblock is a block of load-bearing insulation material with a thermal conductivity of 0.047W/mK strong enough to withstand a load of 9N/mm2. Its function is to eliminate or reduce the thermal bridge at the wall to floor junction. For further information and specifications of Marmox Thermoblock.

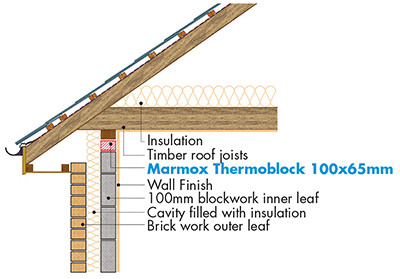

2. Reducing Thermal Bridging in Wall to Roof Junction Designs

Cold bridges also occur at the eaves. Placing Marmox Thermoblock at the junction can eliminate this heat loss and considerably reduce the condensation risk.

3. Reducing Thermal Bridging in Balcony Designs

Balconies are effectively massive thermal fins on the sides of buildings often responsible for losing a significant amount of heat. Traditionally, balconies have been constructed by extending the concrete slab through the wall into the outside. Such a balcony design is a prime example of a thermal bridge which allows the heat within the building to easily escape along that concrete slab. This will result in condensation, mould growth along with significant heat loss and higher heating costs.

Constructing New, Thermally Efficient Balconies

Steel balconies make use of structural thermal breaks which Marmox do not manufacture. Marmox Thermoblock can however be used in the wall both directly above and below the penetrating slab to thermally isolate the internal wall from the outside.

Renovating Existing Balconies

The heat is pulled out of the building because the internal surface area is considerably less than the external surface area in contact with the much colder temperature. This problem can be reduced by making the external surface area in contact with the cold outside temperature effectively smaller and is achieved by externally insulating the slab with Marmox Multiboard or Marmox Sloping Board, see our Balconies page for more information. All thicknesses of Marmox board are external grade thermal insulation boards and can be fixed using a cement-based tile adhesive to the concrete. By reducing the amount of slab exposed, the value will be reduced.

Offsetting the Cost of Including Thermoblock

Marmox Thermoblocks are not replacement blocks, they are not slightly better versions of aircrete blocks they are pieces of load-bearing insulation designed to eliminate the cold bridge. In terms of pricing therefore they should not be compared with masonry units.

Including one course of Thermoblock to the perimeter of a detached house could add between about £600 to £900 to the build cost.

Considering Payback

Including Thermoblock in structure will reduce heating costs. Studies have shown that not addressing a cold bridge at the wall to floor junction can result in heating costs being 15% higher than they need to be, potentially up to £150 per year extra. Payback is therefore approximately between about 4 to 6 years.

Removing other insulation materials. Replacing a block or a brick with a Thermoblock will clearly be more expensive but other insulation materials can now be removed from perimeter to lintel insulation.

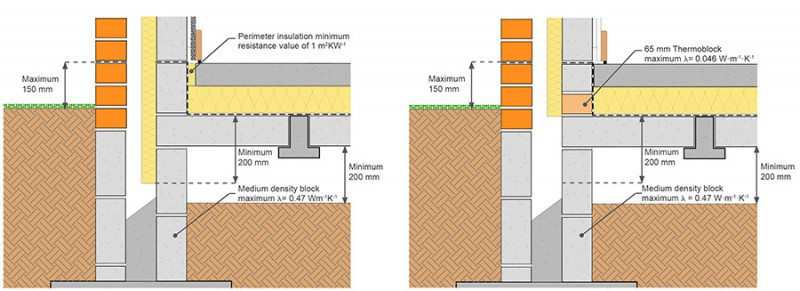

Including Thermoblock in a structure will remove the need for other insulation. Generally, perimeter insulation can be removed, inter-leaf insulation extending into the void can be removed and wall insulation thickness can be reduced. All details will be different but Marmox-UK can provide free thermal modelling to calculate the most cost effective way of achieving an insulation target upon request. Using a better Y value enables less insulation to be used elsewhere. This can often lead to overall lower costs.

Example 1 – removing perimeter insulation, void insulation

In this example, the quantity of rigid wall insulation was reduced from 112sq.m to 103sq.m and the perimeter insulation was removed completely.

Example 2 – Reducing the rigid wall insulation thickness by 20%

A DER of 112W/K was required and initially was be achieved using 125mm of cavity insulation with no thermal bridging block

(100W/K + 12W/K = 112W/K)

00mm thick cavity insulation with thermal bridge insulation gave the same overall insulation

(110W/K + 2W/K = 112W/K)

This resulted in all of the cavity board being the cheaper 100mm thick version instead of the 125mm thick type.

Technical Support

We provide a thermal modelling service (y value calculations) for your junctions to show the effect of incorporating a thermal bridging block. These values can then be used by your SAP or SBEM assessors to reduce your overall emissions rate.